E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Wave-Soldering AOI Inspection Machine - China PCB AOI Machine Supplier Manufacturer

Automatic optical inspection is the full name of the tool that uses optical principles to find frequent flaws in the manufacture of welds. A new testing technology that is coming is wave soldering AOI. Detecting front-end plug-ins in wave soldering, missing plug-ins, reverse plug-ins, incorrect parts, and testing before welding are its main goals. After welding, repair welding is more expensive.

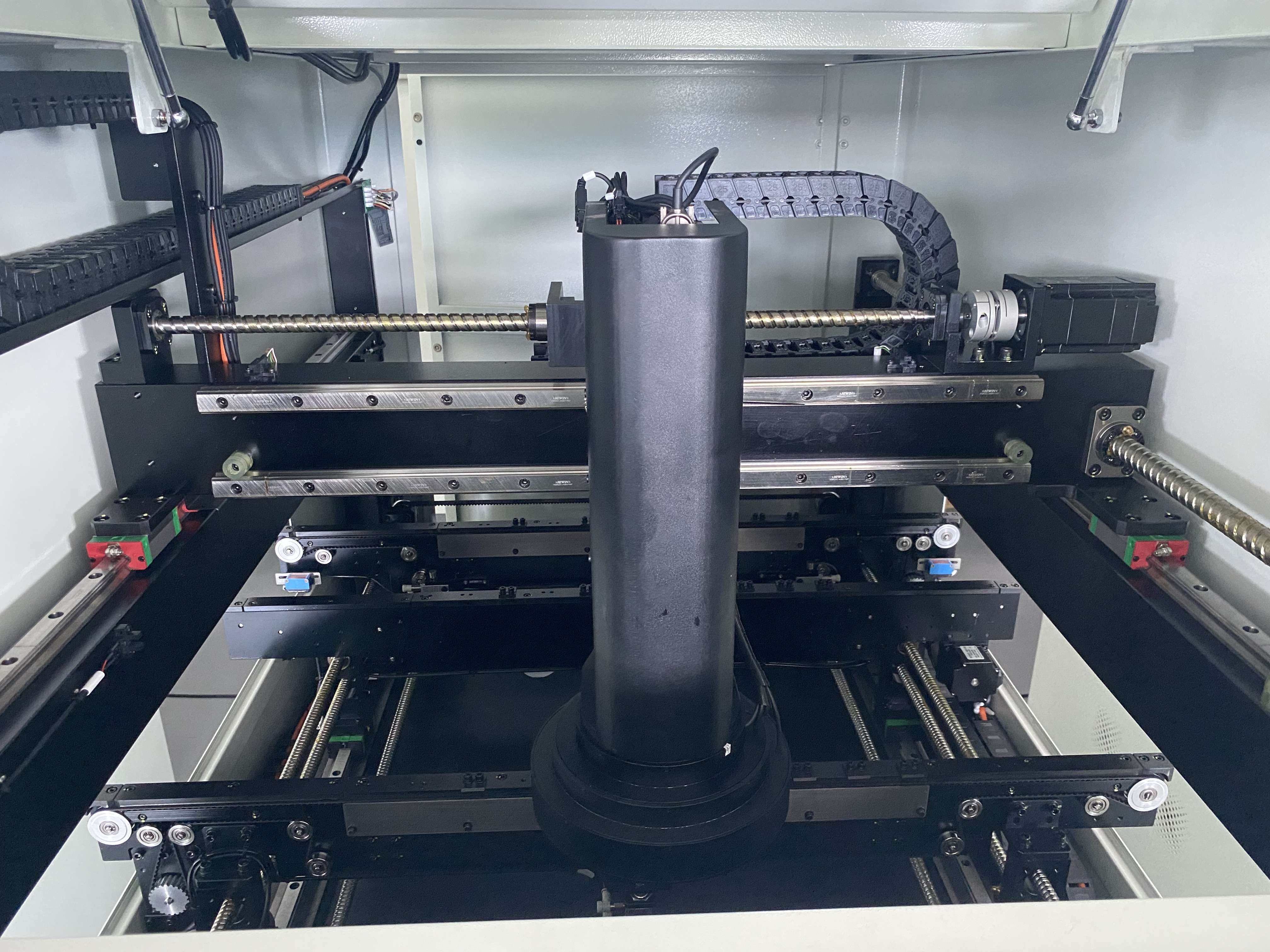

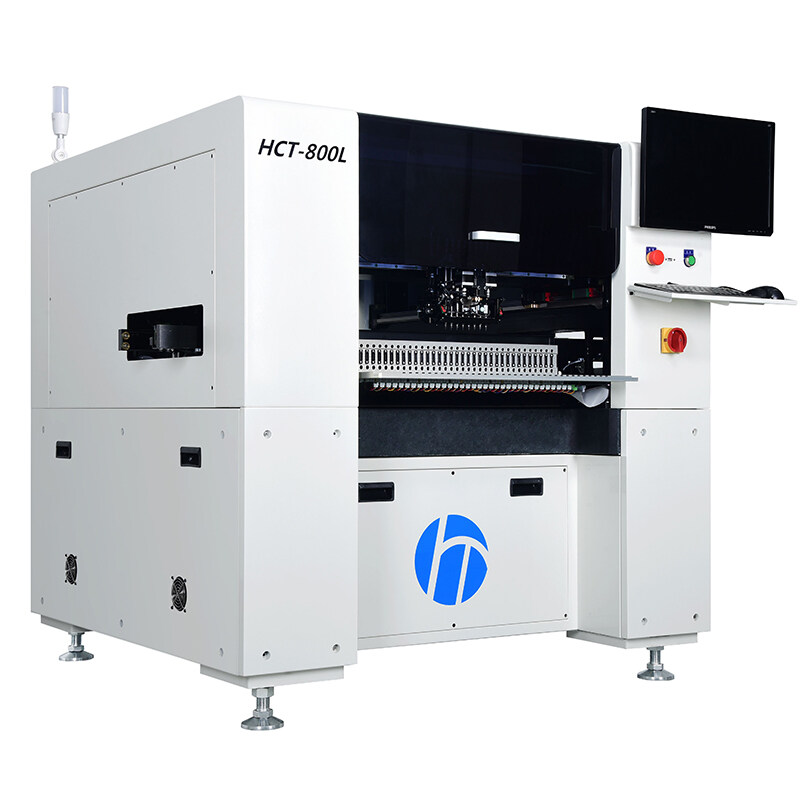

Wave-Soldering AOI Inspection Machine

A Wave-Soldering AOI (Automated Optical Inspection) machine is a specialized equipment used in electronics manufacturing to perform automated inspection of printed circuit boards (PCBs) after they have gone through the wave soldering process.

AOI technology utilizes cameras and image processing algorithms to detect defects, errors, and abnormalities on PCBs. The wave-soldering AOI inspection machine captures images of the PCBs as they move along a conveyor belt during the production process. These images are then analyzed to identify various types of defects, such as missing components, misaligned parts, solder bridges, solder voids, incorrect polarity, and other issues.

The primary purpose of a wave-soldering AOI inspection machine is to ensure the quality and reliability of the assembled PCBs. By automating the inspection process, it not only improves efficiency but also achieves higher accuracy compared to manual inspection. This reduces the chances of defective products reaching the market, saving time and costs associated with rework or customer returns.

Key features of a wave-soldering AOI inspection machine typically include:

- High-resolution cameras: Multiple cameras capture detailed images of the PCB to ensure accurate defect detection.

- Illumination sources: Different lighting techniques are employed to enhance the visibility of various defects.

- Image processing software: Advanced algorithms analyze the captured images to identify defects and compare against predefined criteria.

- Defect classification: The system categorizes defects based on severity, allowing manufacturers to prioritize necessary corrective actions.

- Data management: Inspection results and statistics are recorded, enabling tracking of trends and performance analysis over time.

- Integration capabilities: The machine can be integrated into the production line, synchronizing with other equipment for seamless operations.

- User interface: A user-friendly interface provides operators with real-time feedback, visualization of defects, and options for adjustment or rejection of PCBs.

Wave-soldering AOI inspection machine plays a crucial role in ensuring the quality and reliability of PCBs produced through wave soldering. By automating the inspection process, it improves efficiency, reduces human error, and enhances the overall manufacturing output.

Technical Advantages - AOI Inspection Machine

|

Model |

HCT-AB510 |

|

|

PCB Specifications |

Max. PCB size (X x Y) |

510mm x 460mm |

|

Min. PCB size (Y x X) |

50mm x 50mm |

|

|

PCB Thickness |

0.6mm~6mm |

|

|

Board Edge Gap |

3mm |

|

|

Max. Bottom Gap |

25mm~80 mm Adjustable |

|

|

Max. Top Gap |

25mm~85 mm Adjustable |

|

|

PCB Weight |

Belt Drive:≤10Kg;ChainSprocketDrive:≤30Kg |

|

|

|

AfterWave-soldering |

Chip:wrong parts, missing parts, polarity, offset, tombstone, reverse, damaged, IC bent feet, foreign objects |

|

DIP:Insert pin, no tin, less tin, more tin, hole, dummy solder, solder ball |

||

|

Components Range |

Chip:03015 and above;LSI:0.3mm pitch and above;Others:Special shaped component |

|

|

Inspection Speed |

200~250ms/Fov |

|

|

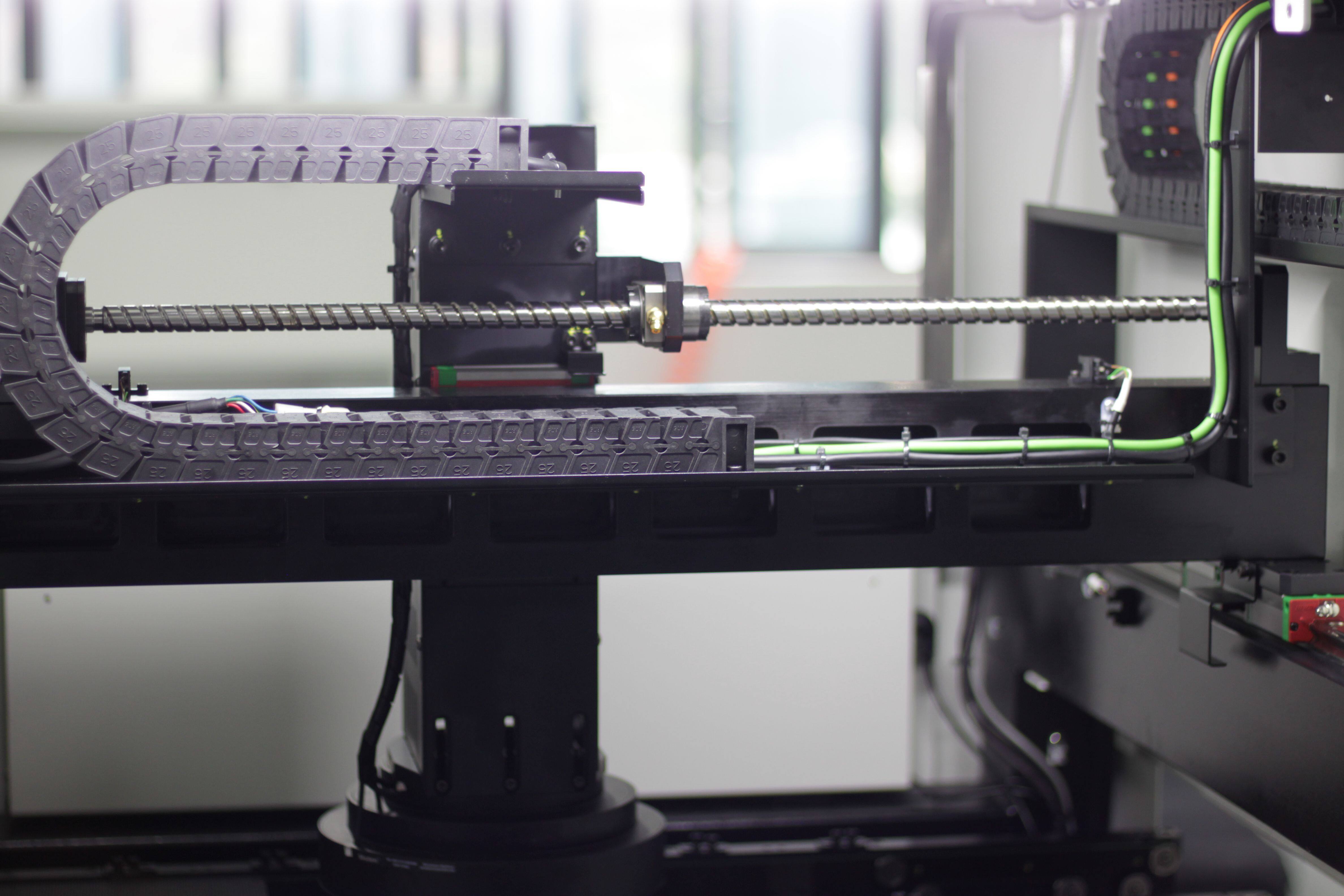

MovementMechanism

|

X/Y Drive |

AC Servo Motor |

|

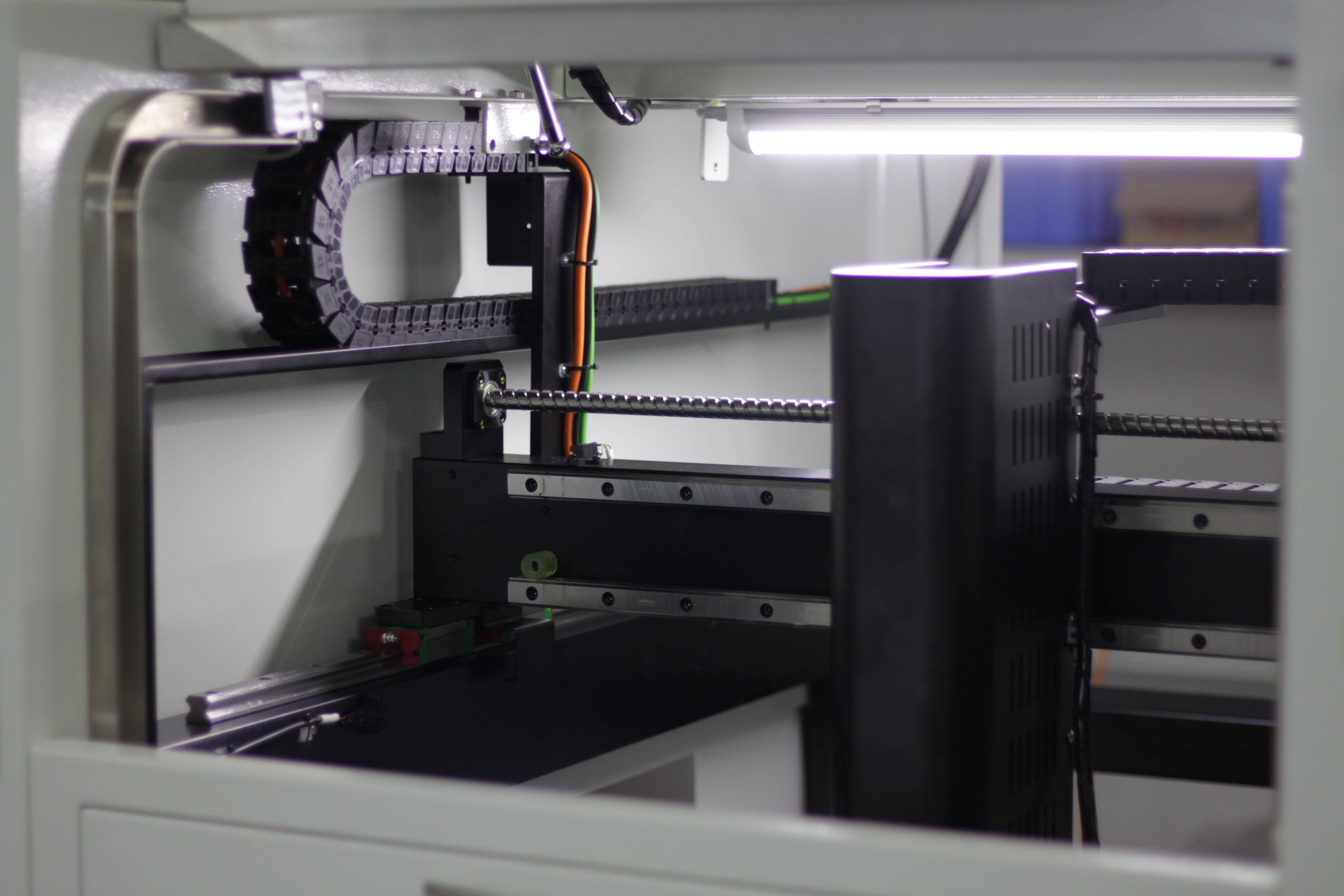

TrackWidthAdjustmentMethod |

Automatic adjustment +Manual adjustment |

|

|

Transmission Speed |

1500mm/s(Max) |

|

|

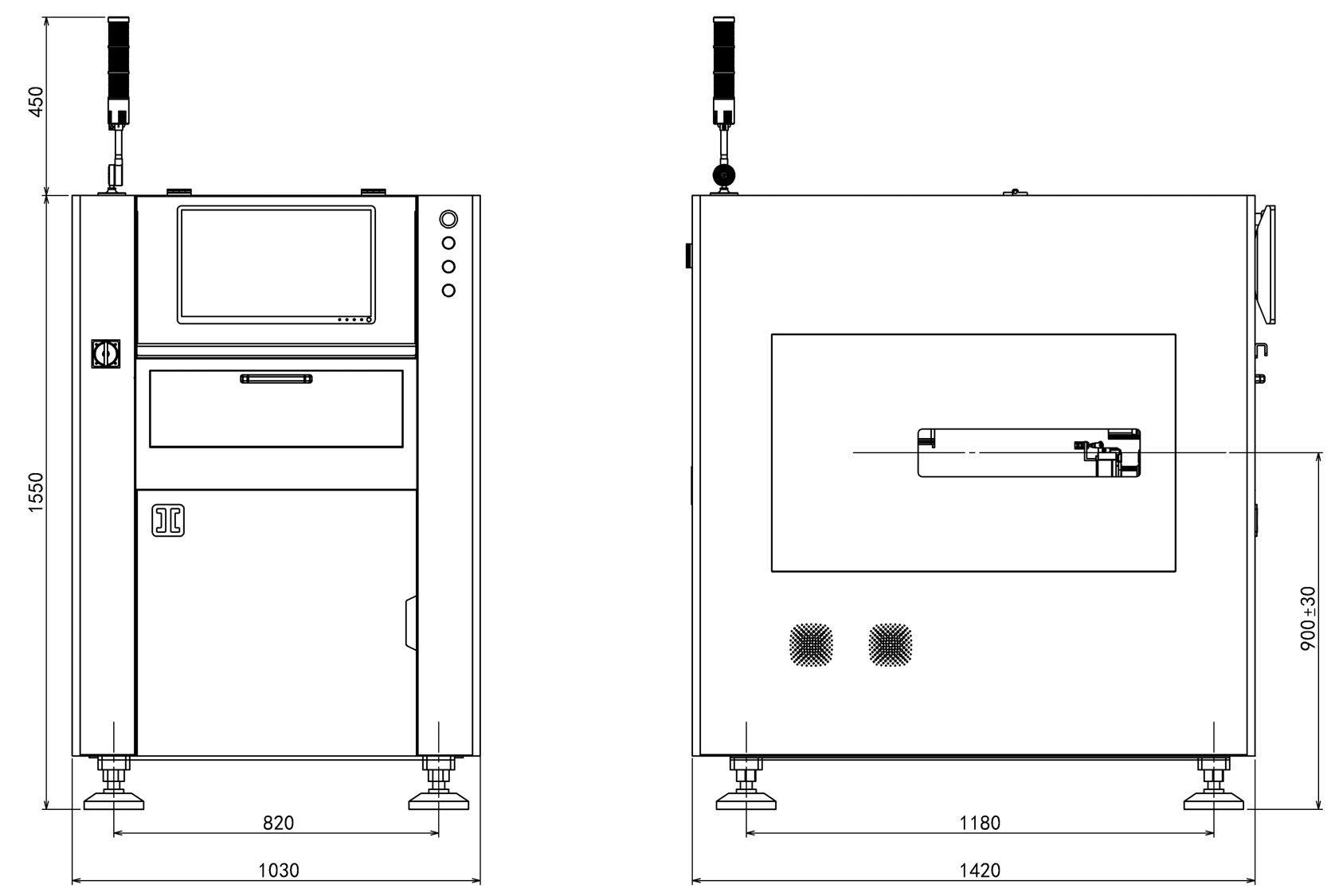

Transmission Height |

740mm±30mm/900mm±30mm (Optional) |

|

|

Transmission Direction |

L – R、R – L、L – L、R – R (Pre-factory setting) |

|

|

Transmission Mode |

Belt drive(Standard ; ChainSprocketDrive is optional |

|

|

Fixed Rail |

Front rail is fixed |

|

|

PCB Clamping Method |

Edge locking + base plate clamping |

|

|

ImageParameters |

Camera |

5MP/12MP Industrial Camera GigE Vision (Gigabit network interface) |

|

Resolution |

5MP:24.5μm(60mm*49mm)、15μm(60mm*49mm);12MP:15μm(60mm*45mm) |

|

|

Lens |

Telecentric Lenses |

|

|

Lighting System |

Multi-angle surrounding 4-color ring programmable LED light source (RGBW) |

|

|

Hardware Configure |

Operation System |

Windows 10 Professional Edition 64-bit |

|

CommunicationMode |

Ethernet,SMEMA |

|

|

Power Supply |

AC220V±10%,50/60HZ,1.8kVA |

|

|

Air Supply |

4~6Kg/cm2 |

|

|

Dimensions |

L(1030mm)×W(1420mm)×H(1550mm)(without alarm lamp height) |

|

|

Weight |

Approx.800kg |

|

|

TemperatureResistance |

Belt drive:≤60℃;Chain Sprocket Drive:≤150℃ |

|

|

AbsoluteHumidity |

25~80%RH4 |

|

Product Features - AOI Inspection Machine

- Multiple positioning algorithms, high-precision inspection

- Minimalist programming, one-click generation of detection windows

- Unique solder joint inspection algorithm, powerful logic function

- It has both SMT, wave soldering, and special-shaped component inspection capabilities

- Unique image algorithm compensation, flexible response to deformed plate inspection

- Combined with SPC inspection data analysis to help improve process quality

- Automatically identify barcodes, quickly query production statistical reports, and remotely view tracking data

- Industry 4.0 management, supervise equipment data, support remote plate making, debugging, support

Technical Advantages - AOI Inspection Machine

SPC warning:

The full name of AOI is automatic optical inspection, which is a device based on optical principles to detect common defects encountered in welding production. Wave soldering AOI is a new type of testing technology that is emerging. It is mainly aimed at the detection of front-end plug-ins in wave soldering, missing plug-ins, reverse plug-ins and wrong parts, and testing before welding. The cost of repair welding after welding is increased.

There are currently two types of AOI wave soldering testing equipment:

1. Detect AOI equipment before wave soldering furnace (mainly detect missing insertion, reverse insertion, and reverse insertion of components)

2. AOI equipment for detecting solder joints after wave soldering furnace (using optical principle to detect false soldering, false soldering and continuous soldering of solder joints, etc.)

Six advantages of wave soldering AOI

1. Wide range of detection types:

It perfectly corresponds to the detection of various components of the plug-in process PCBA.

2. Fast detection speed:

220*180mm size PCBA, inspection speed up to 450pcs/H.

3. Easy to debug:

a. The programming is simple, the same type of components can be programmed with one key using the template, and the public database can be called to save debugging time;

b. It can be debugged offline, and the debugging parameters can be modified without stopping during the production process.

4. Strong detection rate:

Flat-panel TV mainboards, power boards and other products have almost no detection blind spots, which can cover the error, leakage and reverse detection of all plug-in components.

5. High pass-through rate:

When the customer's production process is relatively good, the pass-through rate can reach more than 95%.

6. Large measurable range:

Standard equipment can detect the size range of 330*250mm, and supports customized larger size detection.

Advantages and Prospects of China PCB AOI Machine

China is known for its significant presence in the electronics manufacturing industry, including the production of PCB (Printed Circuit Board) AOI (Automated Optical Inspection) machines. These machines offer several advantages and have promising prospects in the market. Here are some key advantages and prospects of China's PCB AOI machines:

Advantages:

-

Cost-effectiveness: China's PCB AOI machines are often competitively priced compared to machines from other regions. This cost-effectiveness makes them an attractive option for manufacturers looking to invest in AOI technology while keeping their expenses in check.

-

Technological Advancements: Chinese manufacturers continuously invest in research and development to improve the performance and capabilities of their PCB AOI machines. They incorporate advanced imaging technologies, intelligent algorithms, and sophisticated inspection features to achieve higher accuracy and efficiency levels.

-

Customization Options: China's PCB AOI machine manufacturers often offer customization options to suit various production requirements. They can tailor the machines to specific PCB sizes, inspection criteria, and unique manufacturing processes, providing flexibility and adaptability for different applications.

-

High Speed and Accuracy: Chinese PCB AOI machines are designed to handle high-speed production lines, ensuring quick and efficient inspections without compromising accuracy. These machines utilize high-resolution cameras, precise lighting systems, and advanced image processing algorithms to detect defects with great precision.

-

Versatility: PCB AOI machines manufactured in China are versatile and can inspect various types of defects, including solder joint issues, component placement errors, polarity problems, and more. They have the capability to adapt to different PCB designs, components, and assembly techniques.

Prospects:

-

Growing Demand for Quality Control: The demand for PCB AOI machines is expected to rise as the electronics industry places increasing emphasis on quality control. With the growing complexity of PCBs and the need for high reliability, manufacturers will continue to invest in AOI technology to ensure defect-free products.

-

Advancements in Industry Standards: Chinese manufacturers are actively involved in setting industry standards and adopting emerging technologies. This positions them favorably for future opportunities as AOI requirements evolve, ensuring that their machines stay up-to-date with changing industry needs.

-

Global Market Presence: China's PCB AOI machine manufacturers have established a strong presence in the global market. They export their machines to electronics manufacturers worldwide, leveraging their reputation for affordability and quality to expand their market share.

-

Technological Integration: The integration of AOI machines with other equipment and software in the electronics manufacturing process is gaining importance. Chinese manufacturers have the potential to provide integrated solutions that seamlessly connect AOI machines with pick-and-place machines, printers, and other related systems.

If you are looking for a PCB AOI (Automated Optical Inspection) machine supplier and manufacturer, HCT is one option to consider. HCT stands for "High Country Tek" and they specialize in providing advanced inspection equipment for the electronics industry.

HCT offers a range of PCB AOI machines designed to detect defects and ensure the quality of printed circuit boards during the manufacturing process. Their machines utilize high-resolution cameras, sophisticated image processing algorithms, and intelligent software to identify various types of defects such as component placement errors, soldering issues, short circuits, open circuits, and more.

As a supplier and manufacturer, HCT takes pride in delivering reliable and efficient machines that can streamline your production line and improve quality control. They may offer customizable solutions based on your specific requirements, with options for different board sizes, inspection capabilities, and software features.

China's PCB AOI machines offer advantages such as cost-effectiveness, technological advancements, customization options, high speed, accuracy, and versatility. With the increasing demand for quality control, advancements in industry standards, and the manufacturers' global market presence, the prospects for China's PCB AOI machines remain promising in the evolving electronics manufacturing industry.

Product Display - AOI Inspection Machine